Qingdao Kehe refinish chain Co., Ltd.

Dedicated to providing cost-effective consumables and professional equipment for the automotive repair, sheet metal spraying and automotive service sectors

ABOUT US

Get ln Touch Today

Need Assistance? We're Here To Help!

Telephones

Contact Address

No. 1697, West Outer Ring Road, Huangdao District, Qingdao City, Shandong Province

Production and R&D experience

Factory building area of 7,000 square meters

Annual production capacity of over 400 40-foot high cabinets

Patented technology

Global automotive aftermarket innovation solution provider

Qingdao Kehe Supply Chain Co., Ltd. (established in 2025) is a subsidiary of Qingdao Kehe Tools Co., Ltd. specializing in international trade, focusing on providing cost-effective sheet metal spray consumables, professional equipment, and maintenance tools for the global automotive aftermarket. Relying on the mature R&D and production system of our own factory, we are committed to becoming an innovative partner in the field of automotive repair services, helping customers improve efficiency and reduce costs.

The company covers an area of 15 acres and has a factory building area of 7000 square meters. It is equipped with 30 advanced equipment such as high-speed injection molding machines, cup making machines, and high-speed printing machines. The monthly production capacity reaches 30 40 foot high cabinets, and the annual production capacity exceeds 400 40 foot high cabinets. The company's products are mainly exported, covering markets in Europe, America, Russia and other regions, with an export share of 100%.

As an innovation driven enterprise, Qingdao Kehe Supply Chain Co., Ltd. attaches great importance to technology research and development and intellectual property protection. It has obtained 20 domestic patents, 25 EU patents, 1 US patent, and has 1 domestic invention patent and 2 EU patents under application. The company has always been guided by market demand, continuously optimizing product performance and user experience, and helping customers improve efficiency and reduce costs through technological innovation. It is committed to becoming a trusted partner in the global automotive aftermarket.

Core Advantages

The company's products are mainly exported, the market covers Europe, America, Russia and other regions, and the export share is 100%.

Self-development and production

With a professional scientific research team, we have successfully developed more than 50 types of auto repair and auto maintenance and sheet metal spraying ancillary products such as spray gun pots, paint mixing cups, adapters, stirring rods, masking films, cushion pads, toner indicators, spot repair blades, film cutting knives, etc., which cover a wide range of application scenarios.

Agile response to the market

Rapid product iteration based on customer feedback and industry trends to ensure technology leadership and practicality.

Stable security of supply

With large-scale production capacity and strict quality and delivery control, we provide reliable support for our customers.

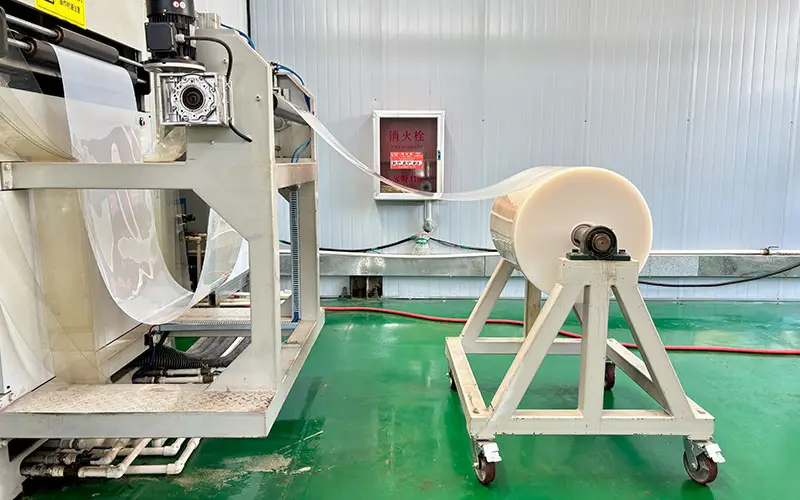

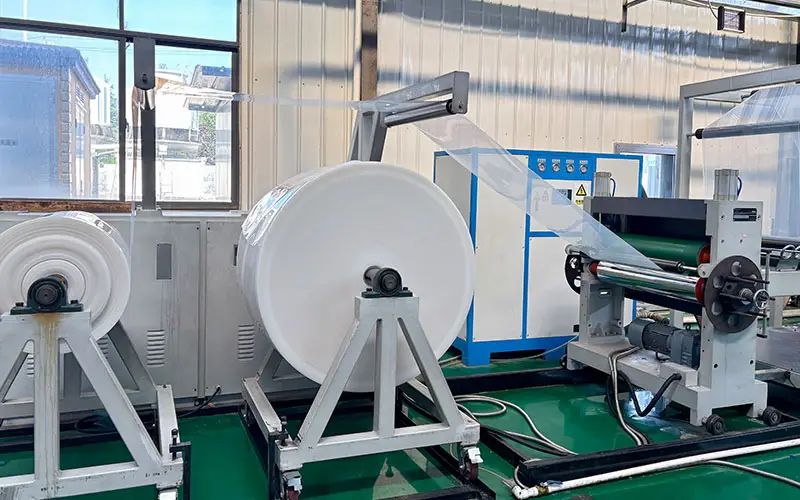

Plant equipment

The company covers an area of 15 acres and has a factory building area of 7000 square meters. It is equipped with 30 advanced equipment such as high-speed injection molding machines, cup making machines, and high-speed printing machines

Factory

Office building

Factory building

Warehouse

Testing Room

Testing Center

Workshop

Workshop

Workshop

Workshop

Workshop

Workshop